I’ll be speaking at PiWars 2021 Virtual Conference, on Sunday 24th January at 12:00 noon. My talk’s about “UKMARS (rotary) encoder project”.

We’ve created a complete replacement for Pololu’s 12mm gear motor magnetic rotary encoders. Our magnetic encoder disk can replace the Pololu encoder’s magnetic disk, and improve the resolution. Our magnetic encoder sensor PCB is a complete replacement for Pololu’s electronics.

BoM cost for each DIY rotary encoder is < £2, about 1/2 Pololu commercial cost (for a finished encoder). So the cost saving is due to your £0 labour cost!

Resolution is 3-4.5x Pololu commercial encoder; Pololu 12 counts/rev (cpr) vs 36-56 cpr.

The two ‘killer’ features of our rotary encoders are:

- The tangential-magnet encoder disk. This doubles the number of sensed magnet poles compared to axial or radial magnetic encoder disks. Hence it doubles the resolution compared to radial or axial magnets. So we get 36 counts/revolution using only 9 magnets. These encoder disks work with Pololu electronics. So, for well under £1/encoder disk, folks can triple the resolution of their existing Pololu encoders.

- The Allegro Micro A12625/A12626 ‘2D’ dual channel, magnetic (Hall) sensors (allegromicro.com). These have a several benefits. There is only one device to mount. So the geometry of the PCB is less constrained than a PCB which needs to provide 90º phase-shift between two sensors. The ‘killer’ feature of the Allegro Micro A12625/A12626 is that it is almost immune to pole spacing. For example, our project has made both 14 magnet axial and 9 magnet tangential magnetic encoders and they both work fine.

It’s worth looking into the Allegro Micro A12625/A12626 2D, dual channel sensors in a bit more detail. The A12626-part outputs two quadrature sensor signals. So it is a ‘drop-in replacement’ for two individual single (Hall) sensors. This suites our use on UKMARSBot because we have XOR hardware on the mainboard PCB to help efficiently track the ‘edges’ of the two signals. It’s the edges which are used to track movement, velocity (speed and direction) and relative position.

However, Allegro Micro also sell the A12625, which outputs speed and direction instead of quadrature. It contains the XOR hardware. So the speed signal gives exactly the same number of edges as the combined, XOR, quadrature signal. Hence, unlike a couple of dual hall sensors, no loss of resolution. Then, to make it easy to use, the direction signal is guaranteed to be stable before the speed-edge. So code checking the ‘speed’ output’s edge-interrupts is simplified because direction is already stable.

We haven’t tested the A12625 yet. However, the PCB is designed to be compatible, connecting the A12625 speed output to ‘A’ and direction to ‘B’ on the PCB signal-header.

Inspiration for the rotary encoder project came from UKMARSBot, the availability of modest cost 1x1mm magnets (1mm diameter x 1mm long), and Erich Styger’s blog “Custom 3D Printed Magnetic Encoder Disks for Robotics Projects“.

Link to slides: PiWars-vc-2021 ‘UKMARS Rotary Encoder Project” PDF

Link to video: Garry Bulmer The UKMARSBOT encoder project – Talk and Q&A (YouTube)

People at my “UKMARS (rotary) encoder project” talk at PiWars Virtual Conference, asked about buying Pololu Magnetic Encoder Disks part number POLOLU-2599 (pololu.com)

This company, tme.eu, shows the same part “MAGNETIC ENCODER DISC” POLOLU-2599 (tme.eu).

I’ve checked the warehouse level, and they show ’50 in stock at the warehouse’, but no delivery date.

The encoders are £0.60 for 5+. However, that is excluding VAT (£0.72 inc VAT) and excluding shipping. When I tried to order 5, to get the cost of shipping, their website said

Due to the need to change IT systems resulting from Brexit, we have temporarily suspended sales to individual customers and the possibility of registration for new individual customers from the UK.

and

This product is not available for sale in your country.

UKMARS is the United Kingdom Micromouse and Robotics Society.

UKMARS has designed UKMARSBot, an Open Source Hardware and Software micromouse-style robot, able to compete in all 5 major Mocromouse events (line follower and walled-maze).

Hardware and Software at github.com/ukmars.

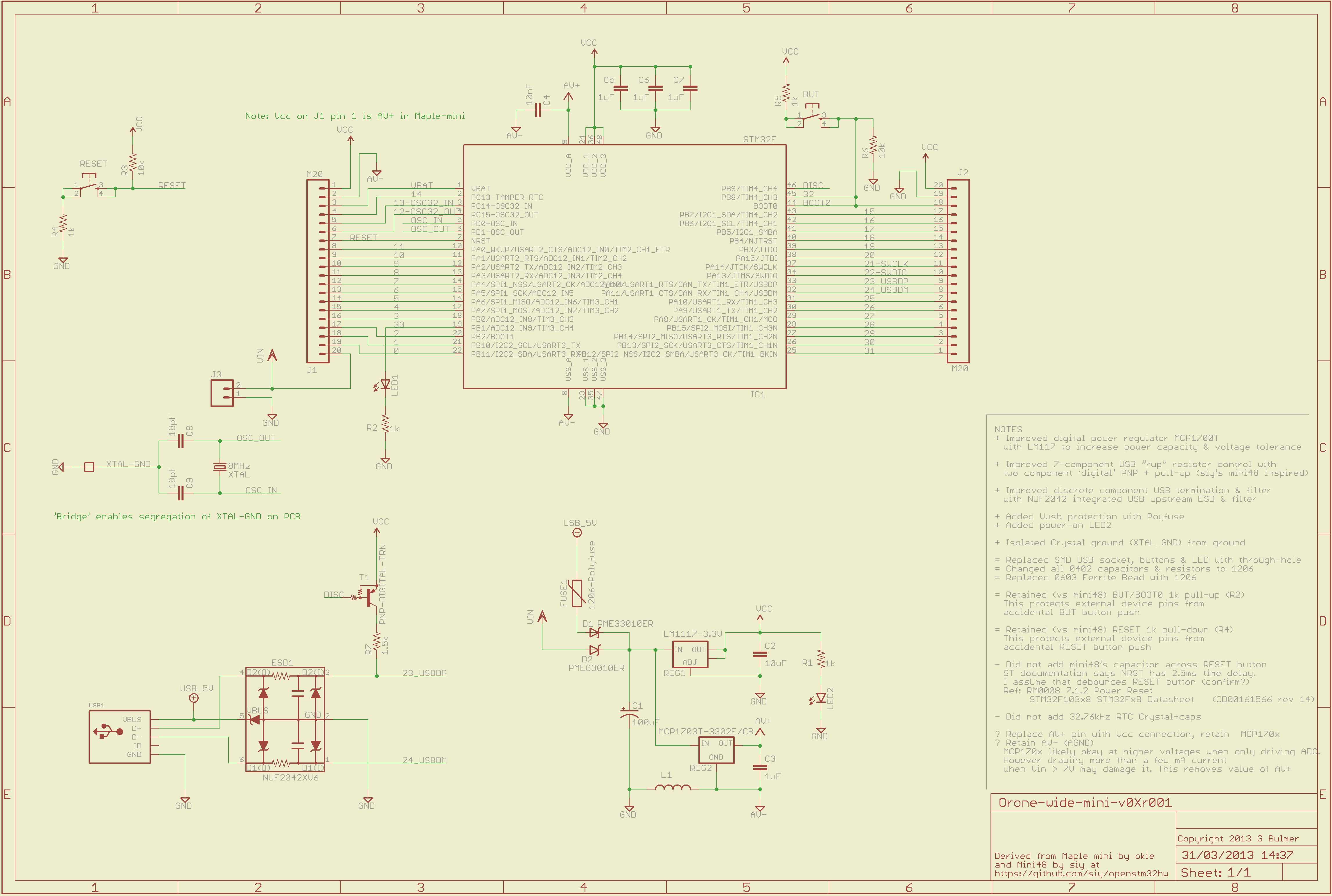

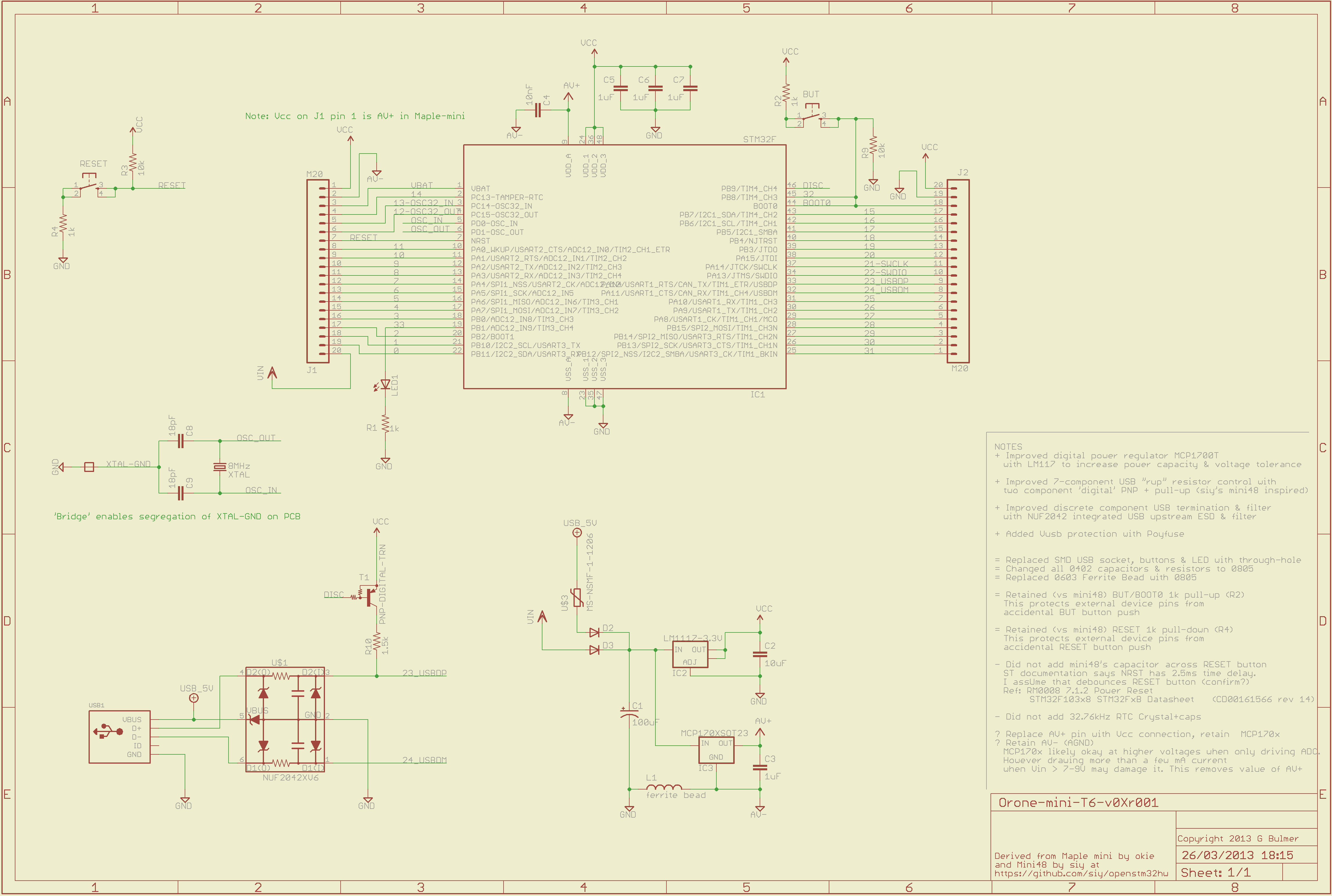

Eagle (v7.6) CAD for the magnetic rotary encoder sensor PCB will be on my github before the end of January.

You must be logged in to post a comment.